|

Specification

|

|

|

General

|

|

|

Indicators

|

Density and variables derived from it (e.g., standard density, concentration, etc.)

|

|

Permissible Media

|

- Particulate-free (<30 μm) hydrocarbons such as

|

|

- Petrol E5 / E10 / E85

|

|

- Diesel B7 / B10 / XTL

|

|

- Jet-A1 (also F-35 or JP-8)

|

|

- M100 (methanol)

|

|

- Isopropanol

|

|

- OME* (synthetic fuel)

|

|

- LPG*

|

|

- Aqueous media such as:

|

|

- AdBlue®*

|

|

- Glycol blends*

|

|

- Other media can be used after individual clarification. *Optional

|

|

Measurement Performance

|

|

|

Max. Measurement Error

|

- Density: ±0.5 kg/m³ (option ±[0.2 or 0.0075 x abs (T-25 °C)] kg/m³ if the value is >0.2)

|

|

- Temperature: ±0.3 °C (option ±0.15 or ±[0.005 x abs (T-25 °C)] °C if the value is >0.15)

|

|

Repeatability

|

- Density: ±0.25 kg/m³ (option ±0.1 kg/m³)

|

|

- Temperature: ±0.1 °C (option ±0.05 °C)

|

|

Temperature Conditions

|

|

|

Permissible Medium Temperature

|

-40 … +60 °C

|

|

Permissible Ambient Temperature

|

-40 … +60 °C

|

|

Permissible Storage Temperature

|

-40 … +60 °C

|

|

Specifications

|

|

|

Permissible Density Measuring Range

|

600…1,000 kg/m³ (option 0…1,200 kg/m³)

|

|

Permissible Viscosity Range

|

0.3…5 mPa s (option 0.3…50 mPa s)

|

|

Permissible Pressure of Medium

|

0…20 bar (abs)

|

|

Burst Pressure

|

80 bar (abs)

|

|

Permissible Particle Size

|

Max. 30 μm

|

|

Permissible Flow Rate Range

|

0…10 l/h (water)

|

|

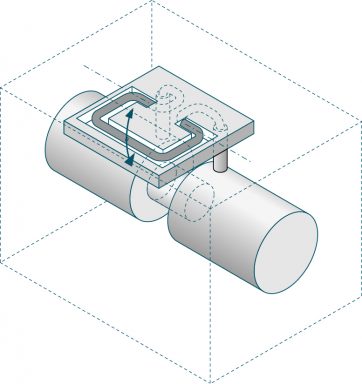

Vibrations

|

Vibrations (<20 kHz) have no influence on the measuring accuracy due to the high working frequency of the microchannel.

|

|

Inlet and Outlet Sections

|

Inlet and outlet sections have no influence on the measuring accuracy.

|

|

Ambient Conditions

|

|

|

Climate Class

|

Not yet defined

|

|

Electromagnetic Compatibility

|

EMC 2014/30/EU (EN 61326-1)

|

|

Vibration and Shock Resistance

|

Not yet defined

|

|

Degree of Protection

|

IP54 (IEC 60529)

|

|

Material

|

|

|

Housing

|

- Stainless steel:

|

|

- 1.4404 (316L)

|

|

- 1.4542 (AISI/SUS 630)

|

|

In Contact with Media

|

- Stainless steel:

|

|

- 1.4542 (AISI/SUS 630)

|

|

- BOROFLOAT® 33 glass

|

|

- Silicon

|

|

- Epoxy resin

|

|

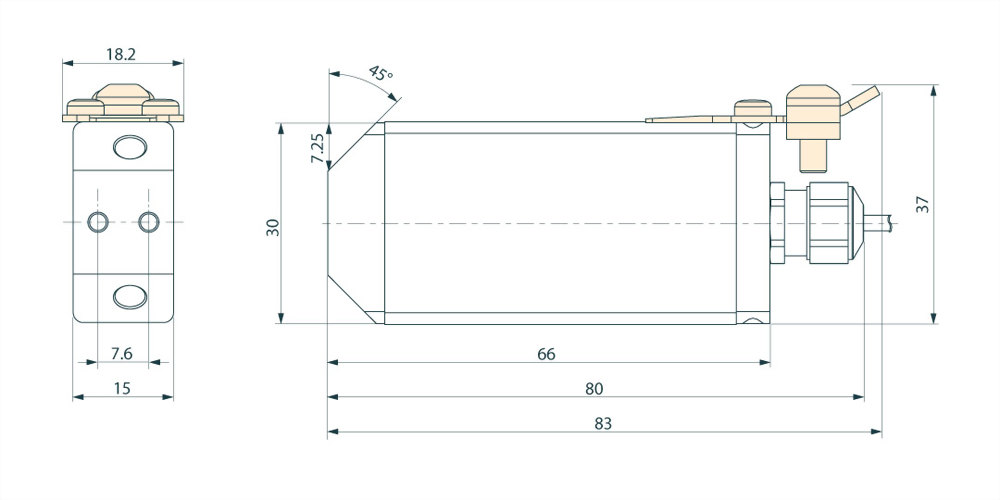

Design

|

DLO-M2_ex

|

|

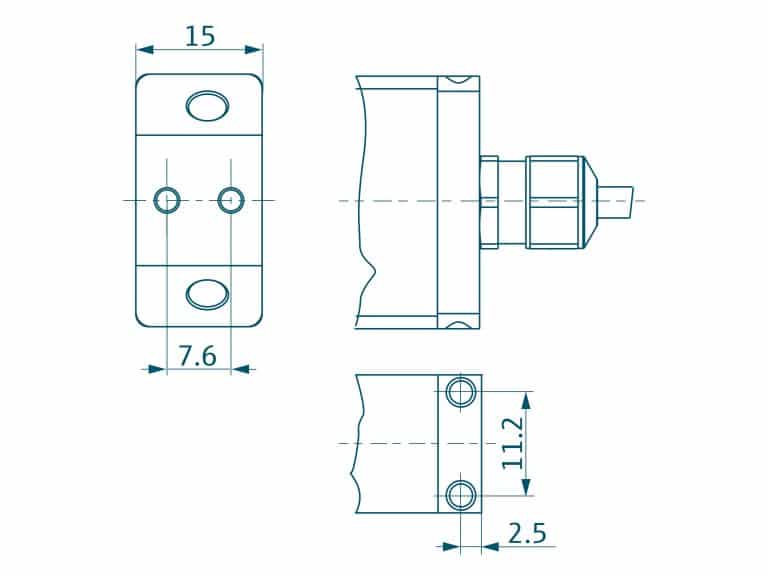

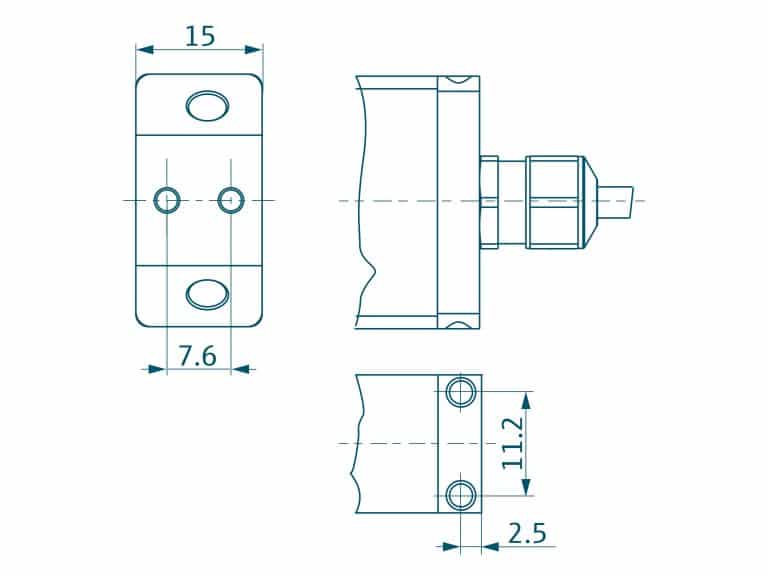

Dimensions

|

30 mm x 66 mm x 15 mm (without cable, cable gland, and connection for protective ground)

|

|

Weight

|

<200 g

|

|

Dimensions of Measuring Channel

|

160 x 200 μm (500 nl)

|

|

Fluidic Interfaces

|

2 x M5 threaded holes at a 45° angle to the side and front surfaces

|

|

Electrical Interface

|

|

|

Communication

|

- Continuous, without the need for an external command.

|

|

- On the hardware standard RS485.

|

|

- Proprietary Modbus RTU communication protocol (see data sheet)

|

|

Cable Design

|

- Permanently installed cable. Connection cable type KS-Li9YD11Y 4xAWG 28, manufacturer: Kabel Sterner

|

|

Cable Length

|

3 m (option up to 30 m)

|

|

Cable External Diameter

|

2.3 mm

|

|

Wire Diameter

|

4 x AWG 28

|

|

Level Control

|

- Digital communication lines and power supply in one common shielded cable, unidirectional, RS-485

|

|

- Provide termination resistance of 330 Ω on the client side

|

|

Energy Supply

|

- Maximum current consumption 26 mA

|

|

- Maximum power consumption 350 mW

|

|

- Supply: 9.4 V…13.3 V (type: 12 V)

|

|

- For DLO-M2_ex XA observe safety instructions – Zener barriers (supply and RS485)

|

|

Dielectric Strength

|

- The reference potential (GND) is connected to the housing and the earth connection (see product structure). There is no electrical isolation between the supply circuits, the communication interface, and GND

|

|

Data Rate

|

- Response time 100 ms

|

|

Cable Assignment

|

Wire color assignment

|

|

- yellow – RS485 B, D1

|

|

- green – RS485 A, D0

|

|

- brown – GND (signal ground), common

|

|

- white – VDD (supply voltage)

|

|

- blank – shielding

|

|

Certificates / Approvals

|

|

|

CE Mark

|

- The density sensor meets the legal requirements of the EC directives. TrueDyne Sensors AG confirms successful testing of the density sensor with the attachment of the CE mark.

|

|

Directives

|

- ATEX 2014/34/EU (L96/309)

|

|

- LVD 2014/35/EU (L96/357)

|

|

- EMC 2014/30/EU (L96/79)

|

|

- RoHS 2011/65/EU (L174/88)

|

|

Standards

|

- EN 61010-1:2010

|

|

- EN IEC 60079-0:2019

|

|

- EN 60079-11:2012

|

|

- EN 61326-1:2013

|

|

- EN 61326-2-3:2013

|

|

- EN 50581: 2012

|

|

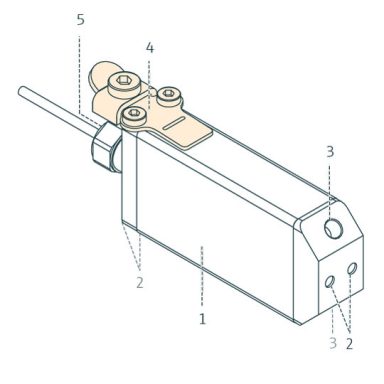

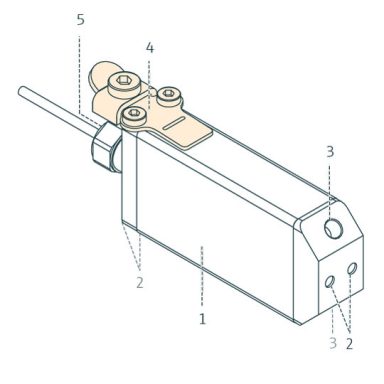

Product Structure

|

|

|

- Density sensor DML02(_ex)

|

|

- Mounting holes for mechanical fastening (6 x M3 threaded holes)

|

|

- Fluidic interface (2 x M5 threaded holes)

|

|

- Clamp on earthing plate with screws M3×8 TORX

|

|

- Electronic interface for communication and power supply

|

|

|

|

Mechanical Fastening

|

DLO-M2_ex

|

![]()